- Power BI forums

- Updates

- News & Announcements

- Get Help with Power BI

- Desktop

- Service

- Report Server

- Power Query

- Mobile Apps

- Developer

- DAX Commands and Tips

- Custom Visuals Development Discussion

- Health and Life Sciences

- Power BI Spanish forums

- Translated Spanish Desktop

- Power Platform Integration - Better Together!

- Power Platform Integrations (Read-only)

- Power Platform and Dynamics 365 Integrations (Read-only)

- Training and Consulting

- Instructor Led Training

- Dashboard in a Day for Women, by Women

- Galleries

- Community Connections & How-To Videos

- COVID-19 Data Stories Gallery

- Themes Gallery

- Data Stories Gallery

- R Script Showcase

- Webinars and Video Gallery

- Quick Measures Gallery

- 2021 MSBizAppsSummit Gallery

- 2020 MSBizAppsSummit Gallery

- 2019 MSBizAppsSummit Gallery

- Events

- Ideas

- Custom Visuals Ideas

- Issues

- Issues

- Events

- Upcoming Events

- Community Blog

- Power BI Community Blog

- Custom Visuals Community Blog

- Community Support

- Community Accounts & Registration

- Using the Community

- Community Feedback

Register now to learn Fabric in free live sessions led by the best Microsoft experts. From Apr 16 to May 9, in English and Spanish.

- Power BI forums

- Forums

- Get Help with Power BI

- Desktop

- Re: Sum up columns based on date

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sum up columns based on date

I have 3 tables of data below. "Current Inventory", "Open requisition orders" to resupply inventory, and "Production Schedule Demand". I am wanting to calculate at what point we will run out of inventory based on the current information.

| Current Inventory | |

| Part # | Unrestricted stock |

| Motor | 1 |

| Alternator | 0 |

| Pulley | 5 |

| Panel | 16 |

| Open requisition orders | ||

| Part # | Delivery date | Quantity |

| Motor | 6/22/2022 | 5 |

| Alternator | 7/21/2022 | 3 |

| Pulley | 7/21/2022 | 10 |

| Panel | 7/21/2022 | 1 |

| Motor | 8/24/2022 | 5 |

| Pulley | 9/1/2022 | 10 |

| Panel | 9/1/2022 | 5 |

| Production Schedule demand | |||||

| Part # | Job # | Required Quantity | Required date | ||

| Motor | 12345 | 1 | 7/1/2022 | ||

| Alternator | 12345 | 2 | 7/1/2022 | ||

| Pulley | 12345 | 6 | 7/1/2022 | ||

| Panel | 12345 | 2 | 7/1/2022 | ||

| Motor | 67890 | 3 | 7/30/2022 | ||

| Alternator | 67890 | 6 | 7/30/2022 | ||

| Pulley | 67890 | 6 | 7/30/2022 | ||

| Panel | 67890 | 2 | 7/30/2022 | ||

| Motor | 98765 | 3 | 7/31/2022 | ||

| Alternator | 98765 | 6 | 7/31/2022 | ||

| Pulley | 98765 | 6 | 7/31/2022 | ||

| Panel | 98765 | 2 | 7/31/2022 | ||

| Motor | 43210 | 1 | 9/1/2022 | ||

| Alternator | 43210 | 2 | 9/1/2022 | ||

| Pulley | 43210 | 6 | 9/1/2022 | ||

| Panel | 43210 | 2 | 9/1/2022 |

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

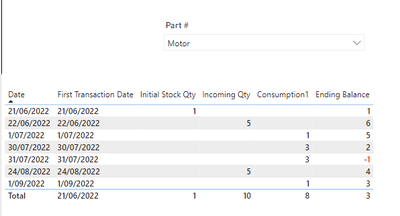

Hi @bstrak1287

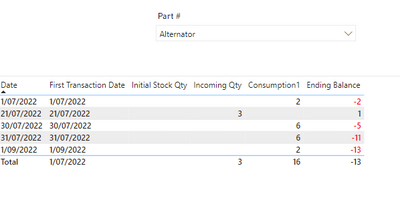

Refer to below as the value displayed -13 for alternator.

Logic used

current inventory (add a date column which can be 1 day less (Minimum value) than your purchase order/sales order).

Make one table with all data included as below.

current inv - Inital stock.

purchase order - Incoming qty

Work/sales order - consumption.

Create a data table 1 day earlier (as initial stock) and last date as maximum of (work order / purchase order).

You can download the file from below and work around.

https://drive.google.com/file/d/1Bl5qSBtGrnHRhEgN9Sn1kfgQp1gHHFuV/view?usp=sharing

Refer to Enterprise DNA, SQLBI for Inventory dashboard.

Let me if this solution is accepted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi bstark,

I think required qty is missing production schedule.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@indkitty apologies it was there, it was just formatted in a way it was tough for me to even discern. I have added columns in between other values to make it easier to read. Thank you for letting me know!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@bstark1287 Not a problem. Have you built Power BI Dashboard (i.e Pbix) file. If yes, can you share through Google drive/One Drive?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I am sorry but I am unable to share due to security settings. I tried just copying and pasting into a dummy powerbi file to attach here but I am not able.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

You cannot add here. Share it with Google Drive/One Drive.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@indkitty I was able to upload it here to my onedrive https://1drv.ms/u/s!ApMyUgRWG_6Cjjd7xDi_TJEZgMSF?e=NZPNbb

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi bstark,

I have built using the data posted.

for motor stock runouts on 31/07/2022 (partial competion of orders).

for alternator

starting inventory itself is 0, it can only run on 21/07/2022 with remaining qty. then following orders are blank.

Let me know if this is what you wanted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@indkitty This is really close to what I am looking for! Can you share how you got these results? Basically I would like to have a slicer for the date so if I select say 7/31/22, it would show I have a negative quantity of 5 alternators which will affect job # 67890. Then if I change my slicer to 9/1/22 it would show alternators with a negative quantity of 13. I think if you share how you got this far I could possibly take it the rest of the way. What you have so far is awesome!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @bstrak1287

Refer to below as the value displayed -13 for alternator.

Logic used

current inventory (add a date column which can be 1 day less (Minimum value) than your purchase order/sales order).

Make one table with all data included as below.

current inv - Inital stock.

purchase order - Incoming qty

Work/sales order - consumption.

Create a data table 1 day earlier (as initial stock) and last date as maximum of (work order / purchase order).

You can download the file from below and work around.

https://drive.google.com/file/d/1Bl5qSBtGrnHRhEgN9Sn1kfgQp1gHHFuV/view?usp=sharing

Refer to Enterprise DNA, SQLBI for Inventory dashboard.

Let me if this solution is accepted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi, @bstark1287

Can you share your expected results for further research?

Best Regards,

Community Support Team _ Eason

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@v-easonf-msft I would like something very similar to the attached below. I have a slicer for the date which affects a custom measure (unrestricted stock - production schedule demand + open requisition orders). I would like to add a drill through to the part # that would show the production orders creating the cumulative total.

Helpful resources

Microsoft Fabric Learn Together

Covering the world! 9:00-10:30 AM Sydney, 4:00-5:30 PM CET (Paris/Berlin), 7:00-8:30 PM Mexico City

Power BI Monthly Update - April 2024

Check out the April 2024 Power BI update to learn about new features.

| User | Count |

|---|---|

| 114 | |

| 99 | |

| 82 | |

| 70 | |

| 61 |

| User | Count |

|---|---|

| 149 | |

| 114 | |

| 107 | |

| 89 | |

| 67 |